Tracking the wind turbine output

|

| Assistant Town Planner Gary Crosby at the WTG terminal |

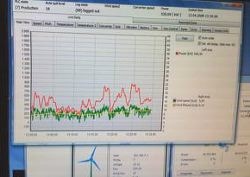

One of the tidbits in last Monday's Portsmouth Town Council meeting was the report that, in its first month of operation, the Wind Turbine Generator (WTG) had made the town approximately $35,000. Earlier this week, I stopped by Town Hall to find out where those numbers come from.

Gary Crosby is Portsmouth's Assistant Town Planner, and he, along with Portsmouth EDC member and Sustainable Energy chair Gary Gump, gave an overview of the monitoring system provided to the town by turbine manufacturer AAER. There are two SCADA terminals in town, one at Town Hall and one at the Fire Department.

"The one at Town Hall is just there to monitor, there is one in the fire station with operational controls," said Gump. "They have a big red button that can start or stop the turbine."

Physically, the "SCADA terminal" is just a web application on a computer sitting next to the rack of gear that occupies a corner of business development director Bill Clark's office. There are several screens of graphical information, showing real-time as well as historical data about all aspects of the WTG's operation.

|

| WTG terminal at Town Hall |

"There are a gazillion sensors," said Crosby. "The datastream goes to [AAER's] Canadian center where they monitor the operational parameters in their surveillance facility. Then the datastream is sent back here."

On that day, the terminal showed that the WTG was producing about 400 kilowatts. The turbine has been set to artificially lower production limits during its run-in period, Crosby explained, as AAER captured wind data to tune the turbine for the local conditions. All of this is covered under the warranty and the maintenance contract with the manufacturer.

But even in these early results, "the averages are what we would expect," Gump said. The turbine produced power for 427 hours since March 18, generating 252 megawatts.

There are two income streams which add up to the $35K number, Gump explained. "One is per Renewable Energy Certificates (REC), which are 4 cents per kilowatt. So 250 [megawatts of] RECs is about $10,000. And the electricity generated, for which the approximate revenue is about 10-11 cents per kilowatt-hour, so between $25-27,000."

The numbers are approximate, because the Town actually gets the generation revenue as an offset against usage. "We'll have to wait till we see our first power bill," said Crosby. "According to regulations from the Public Utilities Commission, we don't get to credit all our accounts, just the top 5 [town meters]."

For the present, the numbers are being posted on the bulletin board across from the Town Clerk's office, but Gump said they are working with AAER to see if they can figure out a way to post the data on the Town web site.

And Crosby and Gump took the opportunity to explain the difference between the Town turbine and the one at the Abbey. They had gotten some questions about why the Town turbine turns more slowly, and why it doesn't appear to spin as often as the one at the Abbey.

"The turbine at the Abbey is always turning; that's a design decision," said Crosby. "But it's not making power until it reaches 28 rpm. Ours will not turn when the wind speed is below 3.3 meters per second [7 mph] but as soon as it starts turning, it is producing power. And it when the wind reaches 11.5 meters per second [25 mph] it is turning as fast as it ever will. Never faster than about 19 rpm. Compared to to the Abbey — at 19 rpm they haven't even started producing yet, but we can generate 2.5 times the power."

|

| Gary Gump explains control panel in WTG. |

Gump had to take some photos inside the turbine, so I tagged along. The first thing you notice, approaching it, is the difference in sound. When you're up close to the Abbey turbine, there is a definite, individual sound as the blade descends, not quite a "whump," but a distinct sound. At the Portsmouth turbine, even standing directly below it, there is only a vague, sustained "whooshing" as the blades rotate. My sense is that it is significantly quieter. Part of it is likely due to the height of the tower, but the aerodynamics of the blades helps.

"The blade technology improves every year," Gump explained.

The loudest sound at the base is actually the hum from the step-up transformer that brings the WTG output of 690 volts up to the 13.5kV for the grid.

There is a bulkhead door at the top of a short flight of metal steps. "The Fire Department has a key," Gump said. Inside the base, there is a central panel showing readouts on the power coming down from the generator, and a control panel on the wall that mirrors the information on the SCADA display. In the middle is s big red button. "That's the emergency stop," said Gump.

There is a thrumming echo inside the tower; not loud, but constant, and you can feel vibration in the walls. "You have to imagine the dynamic stress," said Gump. "The torque from the blade at the top is going to be different than the blade at the bottom."

Outside the turbine, the construction equipment has been removed, but the site is still being restored. Eventually, all the hay bales will be gone and it will look pretty much as it did before. At the base of the approach road, a new National Grid meter tracks the power being generated.

"We haven't looked at that meter," Gump said, "But we're comfortable that the production will be close to the model in the economic feasibility study."

Resources:

Pictures from tour up on Flickr

Visit the Portsmouth Sustainable Energy site for more info.

Visit AAER to learn more about the folks who made the turbine. (Great team picture here.)

Editorial note: Thanks to former water board member Rich Gottlieb for explaining SCADA terminals and setting up the show-and-tell.

Comments

Bruce Ryerson

Sat, 04/18/2009 - 7:37pm

Permalink

There will be no more tilting at windmills for me

Great article John, this crazy thing continues to fascinate me, for awhile I was trying to play the devil's advocate while exploring the facts and figures on wind turbines and I still believe that they are not appropriate to have in every backyard but seeing this thing put together and seeing figures like this make me a true believer.

thanks for the additional info.

John McDaid

Sat, 04/18/2009 - 8:20pm

Permalink

Skepticism is healthy

Hi, Bruce...

As reporters are fond of saying, "If your mother says she loves you, check it out."

It was very reassuring to get a look at the process for tracking the numbers and to see that the early returns, even discounted for the run-in period, are matching expectations.

And I agree -- no one renewable technology is going to be the universal solution. But this one seems like it hit the sweet spot for the town.

Cheers.

-j

gcrosby

Mon, 04/20/2009 - 4:01pm

Permalink

Abbey wind turbine

John -

Thanks for your visit and the excellent posting. I called Brother Joseph at the Abbey just to confirm the information I gave you about their turbine. He has friends in high places and I want to stay on his good side! Their turbine needs approximately 5 meters/sec of wind speed to turn the blades at 28.5 rpms, the minimum rotational speed for making power. Anything below that and the turbine is spinning, but not producing. As the wind picks up from there, the blades will feather to keep the rotor turning at a constant 28.5 rpm, up to a similar max wind speed as ours (20 meters/sec), when both turbines will feather their props and stop turning.

For comparison, ours begins turning at 3.3 meters/sec wind speed and will make power up through the wind range, producing max power (1500 kW/h) at or above 12 meters/sec.

It was a pleasure talking to him, we haven't spoken for awhile. I'm glad you gave me the excuse to make the call.

Gary

John McDaid

Mon, 04/20/2009 - 5:34pm

Permalink

Thanks for the clarification

Hi, Gary...

Thanks for taking the time to explain all this, and thanks for following up.

So the only real difference is that ours starts producing power at 7mph of wind speed, rather than 11mph for the Abbey. Not a big deal. Just could look to someone like theirs is spinning faster and more often. But they are both working the way they were designed.

Cheers.

-j

gcrosby

Mon, 04/20/2009 - 6:40pm

Permalink

only real difference

John -

Yes, but remember that when both turbines are working at max juice, the Portsmouth turbine produces almost 2.5X the power per hour. To torture Karl Marx, "From each according to its ability, to each according to the need." Sly old design optimizer in his own way, eh?

I like to think of it this way. The wife & I use approximately 450 kW per month, so the Portsmouth turbine, when generating at design capacity, takes 3.6 hours to produce enough electricity to last us for a year. The Abbey turbine at design capacity would take a depressing, unbearable, everlasting 8.2 hours to do the same. They both are amazing and beautiful machines and I wish them long and productive lives.

G

John McDaid

Mon, 04/20/2009 - 6:56pm

Permalink

Right, the output, of course

Hi, Gary...

I was just taking as a given that folks knew the Abbey was 660 kilowatt while the Portsmouth turbine is 1.5 megawatt. My bad. Never hurts to be precise.

Cheers.

-j